Our Steel Wheels collection

SSWL manufactures an extensive range of steel wheels, offering various diameters, rim widths, and finishes that can be customized to meet each customer’s functional and aesthetic requirements. With access to multiple steel grades, advanced coating and finishing technologies (such as powder coating and acrylic powder), and specialized processes like flow forming and high vent technology, we provide an impressive array of design options. Drawing on decades of expertise and highly optimized manufacturing processes, we deliver wheels that exceed expectations in both quality and performance. Our steel wheel products include Tubeless, Multi-piece, High Vent Wheels, Semi Fullface, and Weight-optimized (flow-formed) models. Each wheel is manufactured with meticulous attention to detail and undergoes rigorous testing—including corner and radial fatigue tests, impact tests, and bi-axial testing—to ensure outstanding reliability and durability.

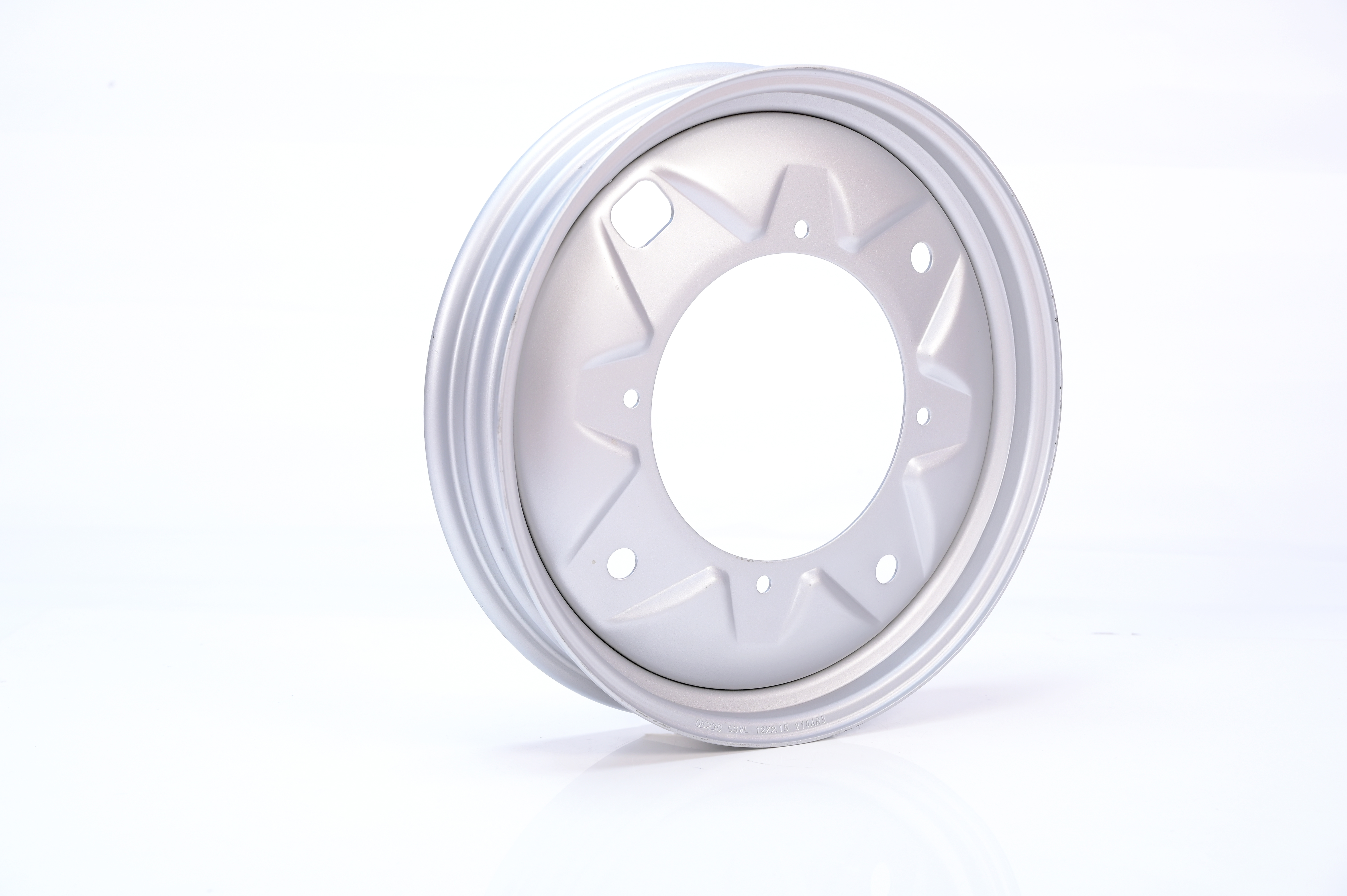

High Vent Wheels

These wheels deploy a design in which window area of the spoke is increased with optimization of strength by structural designing. A custom-designed wheel cover can be added to the rim-&-spoke structure to improve aesthetics aspects without compromising on strength. The optimized structure allows for flexibility in terms of cover design, improves head dispersion and lowers brake temperature. The wheel cover can be replaced with a new design at a relatively cheaper cost, which provides the optionality of multiple designs to the customer. By integrating the flow-forming process in this design, SSWL has been able to produce steel wheels that match the aesthetics of alloy-wheel at a substantially reduced cost.

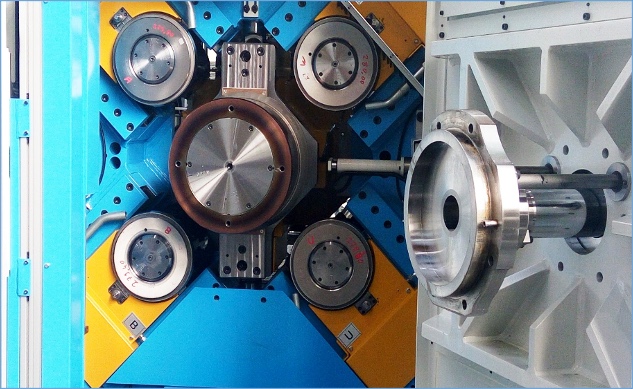

Flow Formed Wheels

These wheels are developed using a weight optimization process with the primary objective to make the wheel lighter for energy conservation and emission reduction. Special flow forming machines, imported from Germany and Japan, are used to achieve a reduction in rim-thickness at low-stress areas of the wheel resulting in a lighter wheel, at the same time the material used in this area is targeted and hardened to ensure that the strength & safety of wheel is not undermined in the process. The flow-formed wheel can help in a reduction of up to 20% of the weight and has a price advantage when compared with alloy wheels.

Presently, SSWL is the only Wheel Supplier in India capable of producing Flow-Formed Steel Wheel Rims for Passenger Car application.

FF Rim successfully developed for European Car maker, PSA-Peugeot-Citroen.