R&D Capabilities

STEEL PASSENGER CAR WHEEL RIM - FF

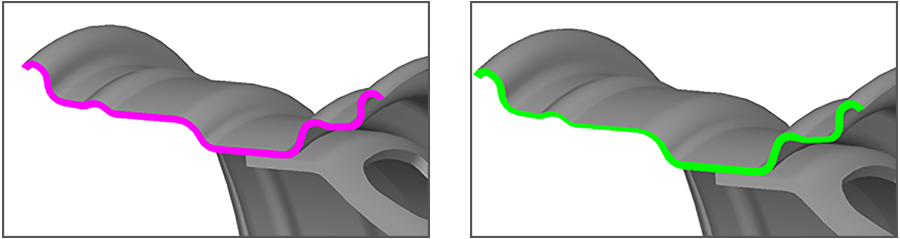

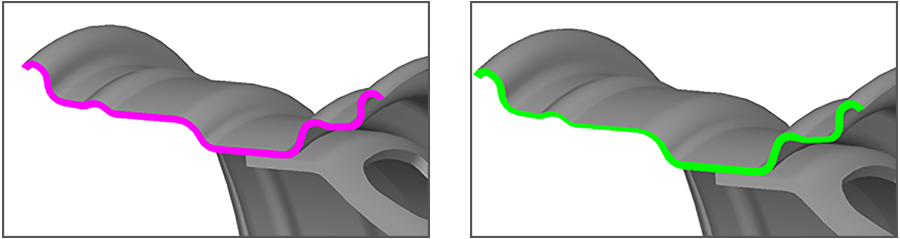

Standard Wheel Flow Form Wheel

Standard Wheel Flow Form Wheel

Optimized Wheel Rim Design for Enhanced Performance

To enhance efficiency and performance, the focus is on reducing wheel rim weight while maintaining structural integrity and functional requirements. This is achieved through the implementation of a variable thickness rim design, strategically identifying regions with lower influence from radial and impact loads. By optimizing material distribution, this approach ensures weight reduction, improved fuel efficiency, and enhanced durability without compromising strength or safety.

➤ Reduction in wheel weight (~5 to 8%) without compromising functional strength lead to fuel efficiency & economy of vehicle.

➤ With flow forming process the grain structure of the rim material will be more refined lead to increase in Tensile strength.

➤ Since flow forming operation is processed after butt welding operation, there is no adverse effect on weld ability.

➤ Presently, SSWL is the only Wheel Supplier in India capable of producing Flow-Formed Steel Wheel Rims for Passenger Car application.

➤ FF Rim successfully developed for European Car maker, PSA-Peugeot-Citroen

Manufacturing Technology : Flow Forming

Current Status: Machine under production

New Product Development & Testing

We specialize in new product development, ensuring seamless execution from concept to final production. Our expertise includes:

✔ Product Design & Validation:

We develop products from scratch, gathering customer requirements and delivering customized, application-specific solutions. The validation process involves FEA analysis, prototype testing, and final approval, ensuring a smooth and timely development cycle.

✔ Radial Fatigue Test (RFT):

We operate one of India’s largest RFT machines, testing wheels up to 44 inches in diameter under realistic load and speed conditions to validate performance.

✔ Cornering Fatigue Test (CFT):

Our CFT machine tests wheels up to 38 inches in diameter, applying bending moment conditions to assess wheel strength and lifecycle durability before production approval.

✔ Coordinate Measuring Machine (CMM):

Our CMM technology ensures that every wheel meets the exact customer specifications, with micron-level inspections to detect any deviations early in development.

✔ Weld Penetration Testing:

We conduct weld penetration analysis using advanced microscopes to verify weld strength, ensuring safe and long-lasting wheels.

✔ Bend Test for Butt Welding:

A 180-degree bend test ensures flawless welding integrity, preventing failures during the wheel forming process.

✔ Field/Track Testing (Customer Collaboration):

We collaborate with customers to conduct extensive field tests, ensuring wheels withstand real-world conditions and deliver top-notch performance in all terrains.

________________________________________Shaping the Future of Mobility

At SSWL, our R&D and Testing Capabilities reflect our commitment to innovation, safety, and product excellence. By continuously pushing the boundaries of wheel manufacturing technology, we empower our customers with high-performance, reliable, and cutting-edge solutions.