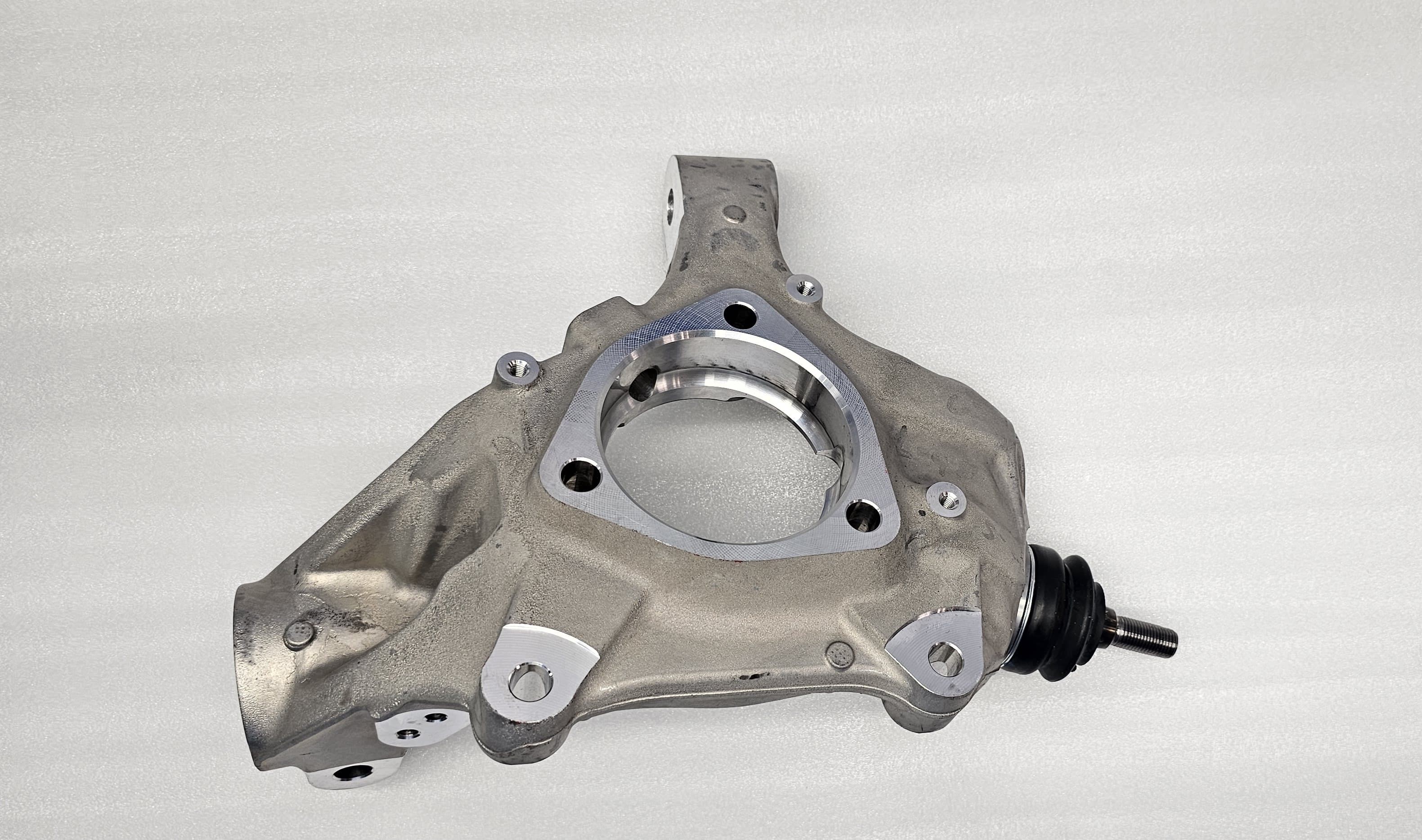

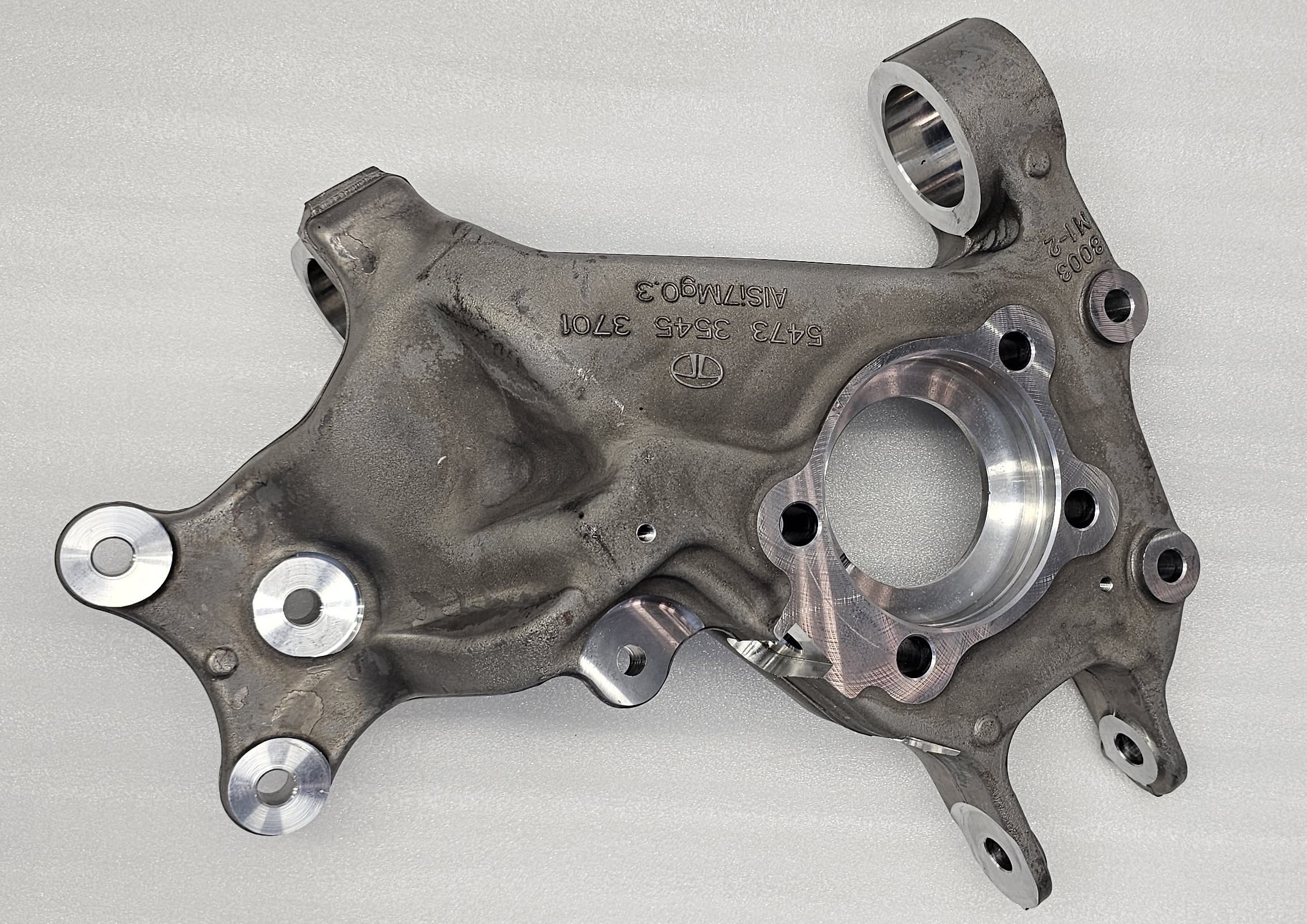

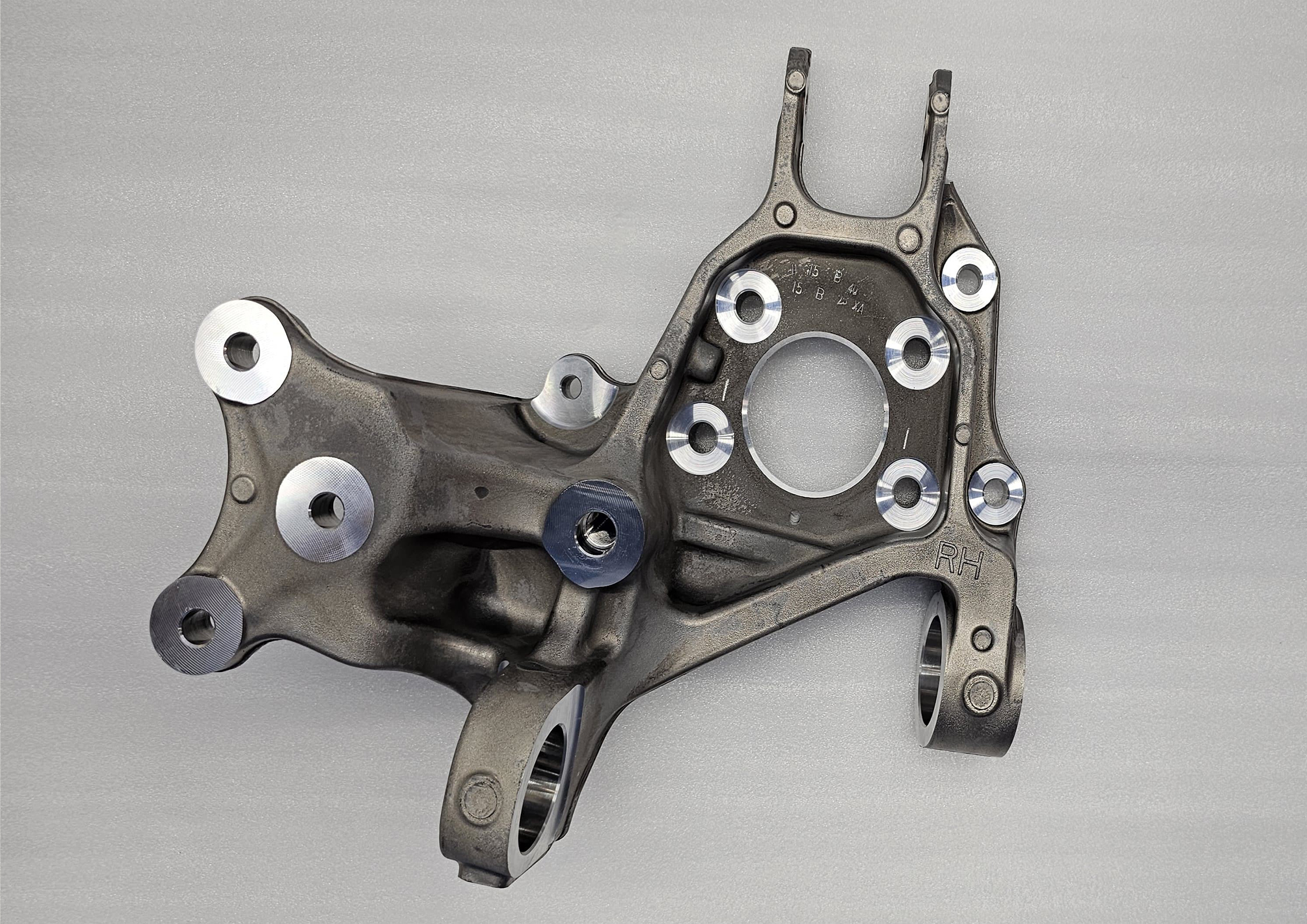

Knuckle

SSWL has expanded its expertise into Alloy Knuckle & lower control arm through Counter Pressure Casting (CPC) process, with our R&D Team leading the way in this innovative endeavour.

The transition from traditional Iron Knuckles to Aluminium Alloy Knuckles represents a significant advancement in the pursuit of light-weighting, sustainability, and enhanced vehicle performance.

Through the utilization of cutting-edge CAD 3D, FEA, and Mold Flow simulation tools, we prioritize structural integrity and safety by conducting thorough analyses of each design.

The incorporation of Aluminium Alloys provides superior resistance to corrosion and wear, making alloy knuckles well-suited for high-stress environments where reliability is paramount.

These meticulously engineered components are casted and precision-machined to exact specifications with our In-house Capability, ensuring optimal performance and durability.